DEHYDRATION PLANT

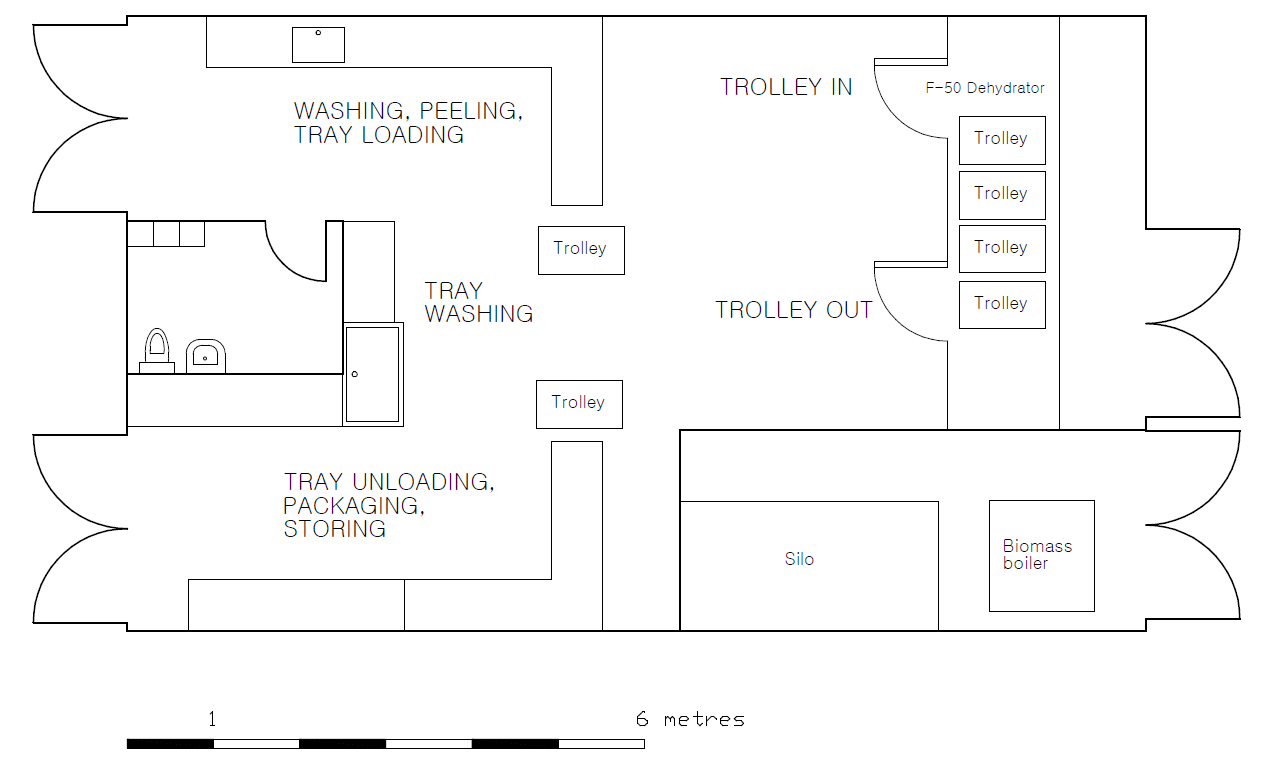

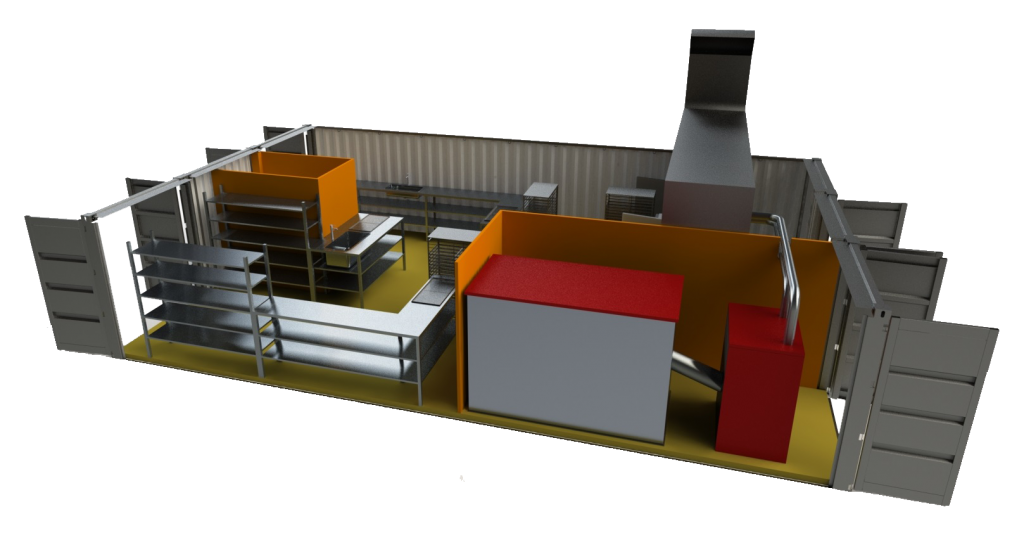

If you do not have the facilities for installing your dehydrator, we can offer a project of a dehydration plant constructed in containers. Installations ready to connect to water and electricity supplies. Biomass boiler. Facilities for pre-washing, washing, peeling, cutting, tray loading and unloading; and packaging.

- Area 86m2

- Metallic structure formed by three 40’HC containers

- Storing shelves made of stainless steel

- Stainless steel worktops

- Stainless steel sinks for product and tray washing

- Toilet and locker

- Approximate plant weight 18Tn

- F-50 Dehydrator

- Biomass boiler

Dehydration plant benefits

This is the perfect solution for those clients that do not have space in their facilities and want to locate the dehydration plant beside those facilities or at the production site.

In its design, it has been taken into account the common criteria demanded by the entities competent in safety and hygiene matters to obtain the future Sanitary Registration that this kind of industries require.

The standard dehydration plant is the one shown in the drawings and is designed to accommodate one F-50 dryer, but in the event of having a higher production capacity and a larger industry with more F-50 dryers is required, and therefore with more space for washing, peeling, cutting, tray loading and unloading and packaging; Foodehy will study a customized plant design.

Since the plant is prepared to be placed at its final location, ready to be assembled and quickly being operational, this solution is perfect for those clients that want to locate the plant at the production site. This facilitates having at the same spot the processing plant from which to prepare dehydrated products, packed and ready to sell.

These cases mean a great save in transport, because foodstuffs (e.g. fruits) are usually harvested at plantations that are considerably far away from the logistics centre. With our solution, the transported product is the final dehydrated product, from which more than 80% of the water has been removed, and therefore each loaded truck is equivalent to 7 or 8 trucks with fresh food, resulting in a saving in terms of transportation.

Moreover, dehydrated products do not need to maintain any cold chain during its transportation, so the saving is even greater.

3D images by ![]()