F-50 INDUSTRIAL DEHYDRATOR

Our F-50 Industrial Dehydrator uses minimal energy, obtaining homogeneous results in reduced time.

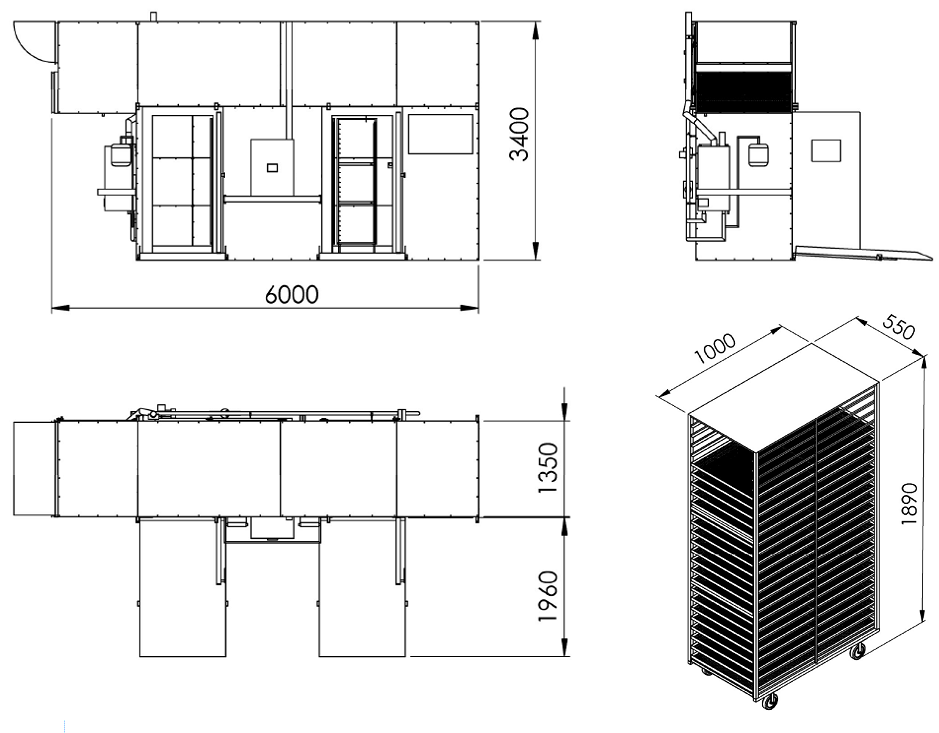

This industrial food dryer is able to work in a continuous (trolleys coming in and out one by one) and discontinuous (batches of several trolleys at a time) production pace, easily adaptable to client needs.

The food dryer is able to work with 1 to 4 trolleys, up to a maximum of 50m2 total tray area.

With a wide range of temperature and air velocity, multiple kinds of food (fruit, vegetables, plants, meat, fish, etc) can be processed and dried in our industrial dehydrator.

- Stainless steel construction

- Electric power < 9kW

- Thermal energy by a < 60kW gas boiler, included (optional biomass boiler or adaptation of existing boiler in client’s facility)

- Adjustable drying air speed

- Maximum drying temperature 70ºC (ask for availability of higher drying temperature)

- Touch screen with real time data of temperature and humidity, among others

- Programmable for continuous (trolleys coming in and out one by one) and discontinuous (batches of several trolleys at a time) process

- Programmable for dehydrating in stages

- Homogeneous dehydration

- Product loading on trays within moving trolleys

- Maximum dehydration area of 50m2

- Stainless steel meshed trays (optional complementary non-stick meshes)

- Product weight control in real time

- Real time control of the dryer with remote access from PC, Tablet or Smartphone

- CE certification

- 1 year guarantee

Process control

The F-50 industrial food dehydrator can thoroughly control all the key variables involved in the dehydration process:

Psychrometic properties of air at various locations of the aeraulic circuit. These variables provide vital information for checking the proper performance of the process and for acting on the system.

Air velocity, closely related to the dehydration velocity and also critical to some products that undergo case hardening during the process.

Air refreshing rate, essential to obtain a low energy consumption without affecting the dehydration velocity.

State of progression of product weight, which allows the user to know the exact moment at which the product reaches the aimed degree of dehydration and, therefore, must be removed from the dryer.

All of this is controlled in real time from the machine interface and also by means of the on-line remote access from PC, Tablet or Smartphone.

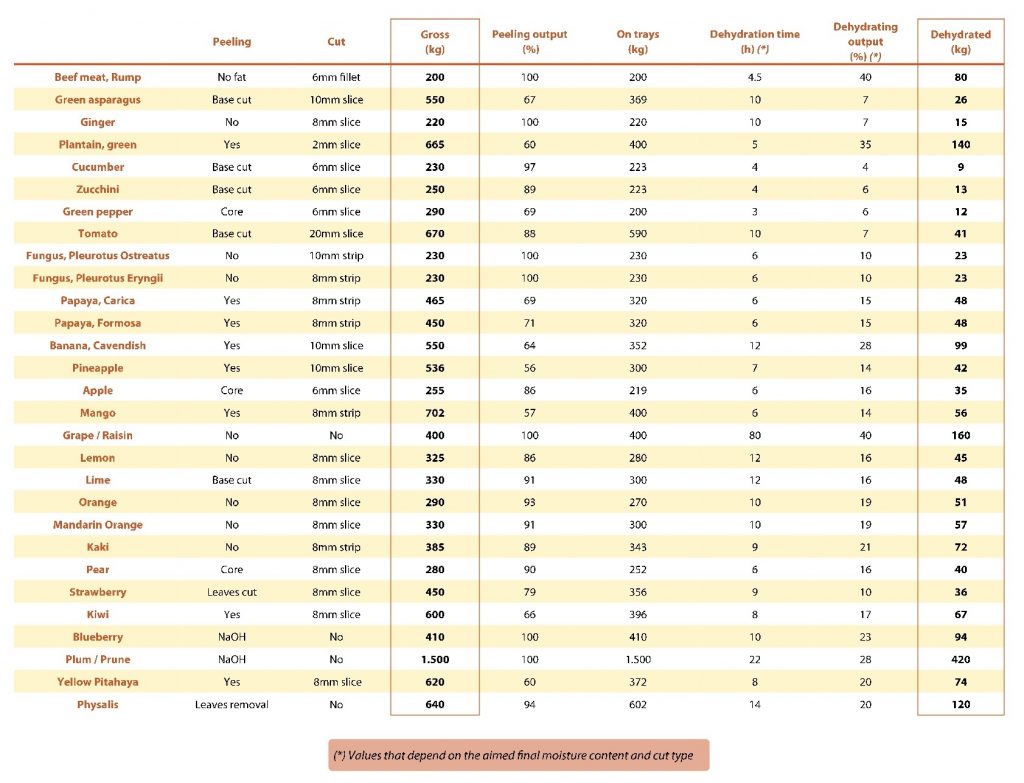

Production capacity

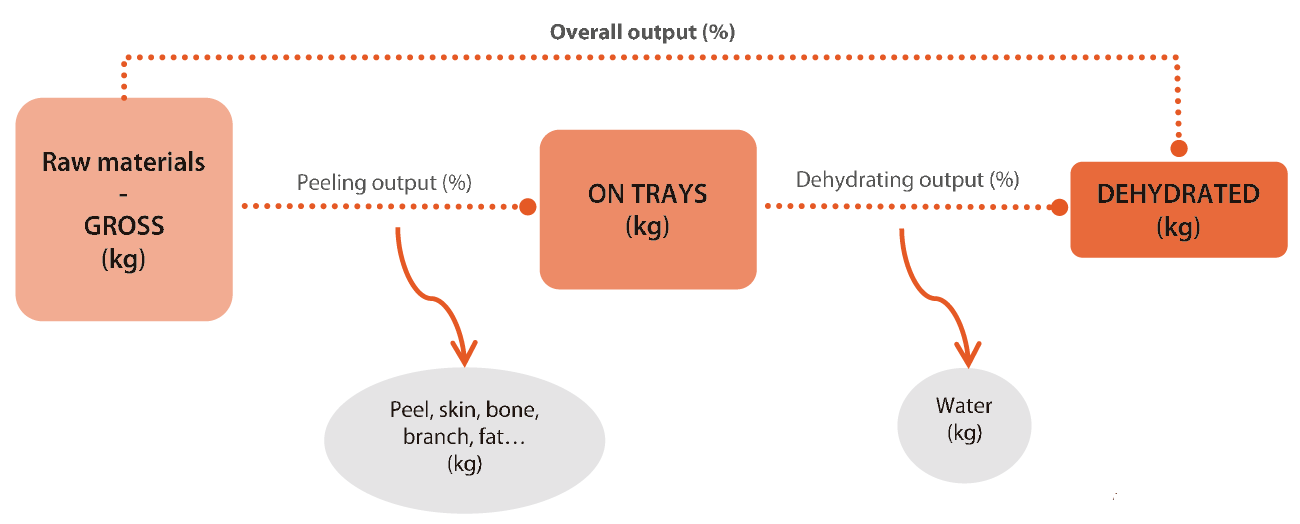

The load capacity of the industrial dryer depends on the properties of the fresh product or food to be dehydrated (weight, size, skin/peel…), the cut type and the tray area.

Some examples are shown in the following table (click on images to zoom):

F-50 Industrial Dehydrator benefits

One of the main advantages of the F-50 industrial food dryer is its ability to achieve high drying velocities using electric and heating resources very efficiently.

The user can adapt the consumption of the electrical source by modifying the air velocity of the fan in the chamber, according to the needs of the product. When the heated air, after passing through the product, still has a drying potential, the F-50 technology detects it and is reused. When the air is discarded into the environment, it is elevated in temperature. It may therefore be used to preheat the incoming cool air, thereby increasing the energy efficiency of the machine and reducing the consumption of fuel.

The drying temperature is a critical variable. Its adjustment is essential for the proper drying of each particular product or food. The F-50 industrial dehydrator allows the dehydration temperature set point to be stationary during the process.

By means of the Programmable Logic Controller (PLC), it is possible to know the psychrometric properties of the air at various locations of the aeraulic circuit, in addition to the weight of the product in real time. The user can control and act on the most important variables during the process of dehydration.

The aeraulic circuit is especially designed to obtain a uniform air flow along all the trolleys and trays and, therefore, obtaining homogeneity in the product drying.

Depending on the user’s needs, it is possible to program a process of continuous (trolleys coming in and out one by one) or discontinuous (batches of 1 to 4 trolleys at a time) dehydration. This is possible thanks to the advantages of our controller and the designed aeraulic circuit.

It is not necessary to completely fill the 50m2 of trays for using the industrial dryer. Partial loads are also optional for very efficient processes.

The user can have total control over the dryer without being at the facility. The dehydrator may be remotely accessed through a PC, Tablet or Smartphone, allowing the user to control and act on the process and to turn the machine off or on at any time.

Easy tray unloading process. To facilitate this process, which is sometimes tedious, we offer the option of adding anti-stick mesh on the trays for those products or foods whose separation from the stainless steel tray is especially delicate.

Companies especially aware and concerned about the environment will have the option of choosing a dehydrator with renewable energies, such as a biomass boiler.

Our conventional but highly improved technologies, maintain the natural nutritional properties of foods at maximum throughout the dehydration process.